Hey there! As a supplier of screw type air compressors, I often get asked this question: Can a screw type air compressor be used for medical applications? Well, let's dive right into it and find out.

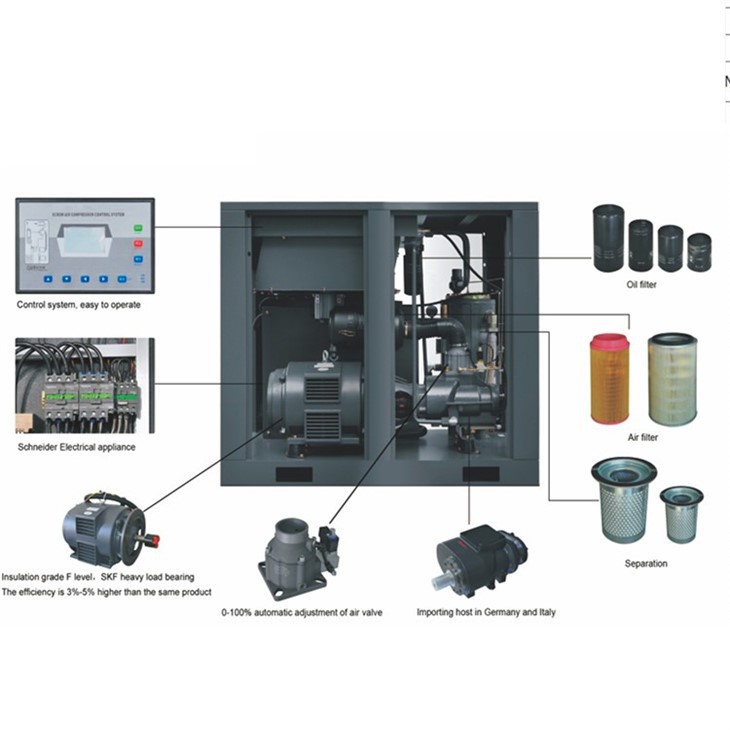

First off, let's talk a bit about screw type air compressors. A Rotary Screw Air Compressor is a type of compressor that uses two meshing helical screws, also known as rotors, to compress the air. They're pretty popular in industrial settings because they're efficient, reliable, and can deliver a continuous supply of compressed air. You can check out more about them on our Industrial Use Screw Air Compressor page.

Now, when it comes to medical applications, the requirements are a whole different ballgame. Medical air systems need to meet strict standards and regulations to ensure the safety and well - being of patients. The air used in medical settings has to be clean, dry, and free from contaminants like oil, dust, and microorganisms.

One of the main concerns with using a screw type air compressor for medical applications is oil contamination. Some screw compressors are oil - flooded, which means they use oil to lubricate, seal, and cool the rotors. If this oil leaks into the compressed air stream, it can be a major problem in a medical environment. Oil can carry bacteria and other harmful substances, and inhaling oil - contaminated air can be dangerous for patients.

However, there are oil - free screw type air compressors available. These compressors are designed to operate without the use of oil in the compression chamber. They use special coatings and materials on the rotors to reduce friction and wear, and they rely on other methods for cooling and sealing. An oil - free Rotary Screw Air Compressor can potentially be used in medical applications as long as it meets the necessary purity standards.

Another important factor is the filtration system. Even if you have an oil - free compressor, you still need a high - quality filtration system to remove any remaining contaminants. This includes filters for dust, bacteria, and odors. The filtration system should be regularly maintained and replaced to ensure its effectiveness.

In addition to air purity, medical air systems also need to have a stable pressure and flow rate. Screw type air compressors are generally good at providing a continuous and stable supply of compressed air. But for medical applications, the compressor needs to be able to accurately control the pressure and flow according to the specific requirements of the medical equipment being used.

Let's look at some of the potential medical applications where a screw type air compressor could be used. One common use is in dental offices. Dental tools like drills and air syringes require a reliable source of compressed air. An oil - free screw compressor, along with a proper filtration system, can provide the clean and dry air needed for these tools.

Another application is in some types of respiratory therapy equipment. For example, some ventilators and nebulizers need a supply of compressed air to function properly. As long as the air meets the strict purity standards, a screw type air compressor could be a suitable option.

However, it's important to note that just because a screw type air compressor can potentially be used in medical applications doesn't mean it's a one - size - fits - all solution. Each medical facility has its own unique requirements, and it's crucial to consult with experts in the field of medical air systems. They can help you determine if a screw type air compressor is the right choice for your specific situation, and they can assist with the proper installation, maintenance, and testing of the system.

Now, let's talk about the benefits of using a screw type air compressor in medical applications if it meets the standards. First of all, they're relatively compact compared to some other types of compressors. This can be a big advantage in medical facilities where space is often limited. They're also energy - efficient, which can lead to cost savings over time. And because they can provide a continuous supply of air, they can ensure that medical equipment operates smoothly without any interruptions.

On the flip side, there are some challenges. As I mentioned earlier, ensuring air purity is a major challenge. The initial cost of an oil - free screw compressor and the associated filtration system can be higher compared to other types of compressors. And regular maintenance is a must to keep the system running properly and to meet the strict medical standards.

In conclusion, a screw type air compressor can be used for medical applications, but only under the right conditions. You need to make sure you have an oil - free compressor, a high - quality filtration system, and a way to accurately control the pressure and flow. If you're considering using a screw type air compressor in your medical facility, it's a good idea to do your research, consult with experts, and make sure you're compliant with all the relevant regulations.

If you're interested in learning more about our screw type air compressors and how they might fit into your medical application needs, feel free to reach out. We're here to help you find the best solution for your specific situation. Whether you're a small dental office or a large hospital, we can work with you to ensure you get a reliable and high - quality compressed air system.

References

- ASHRAE Standard 62.1 - Ventilation for Acceptable Indoor Air Quality

- NFPA 99 - Health Care Facilities Code

- ISO 8573 - Compressed air - Purity classes