Hey there! As a supplier of Screw Type Air Compressor, I've been getting a lot of questions lately about the air quality output of these machines. So, I thought I'd take some time to break it down for you all.

First off, let's talk about what a screw type air compressor is. It's a kind of compressor that uses two meshing helical screws, also known as rotors, to compress the air. They're super popular, especially in industrial settings, 'cause they can deliver a continuous flow of compressed air. There are different types, like Rotary Screw Air Compressor and Industrial Use Screw Air Compressor, each designed for specific needs.

Now, onto the main topic - air quality output. The air quality from a screw type air compressor can vary depending on a few factors. One of the key things is the level of contaminants in the compressed air. Contaminants can include things like oil, water, and solid particles.

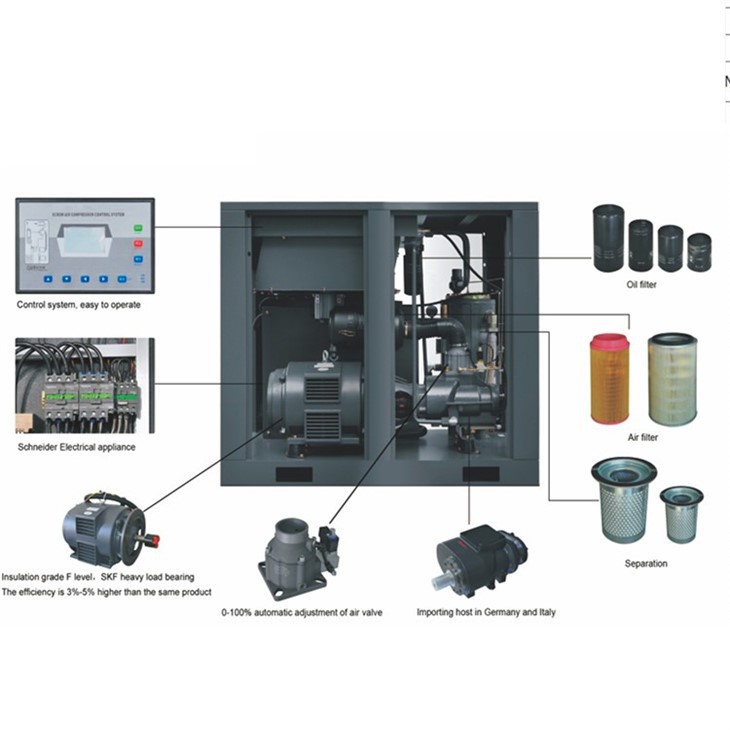

Let's start with oil. In oil-injected screw compressors, oil is used to lubricate, cool, and seal the rotors. While this helps the compressor work efficiently, it can also lead to oil carryover in the compressed air. The amount of oil carryover depends on the design of the compressor and the quality of its oil separation system. High - quality compressors are equipped with advanced oil separators that can reduce the oil content in the compressed air to very low levels, sometimes as low as 0.01 ppm (parts per million).

Water is another common contaminant. When air is compressed, its temperature rises, and the water vapor in the air can condense. If this water isn't removed, it can cause corrosion in pipes, damage pneumatic tools, and affect the quality of the end - product in some manufacturing processes. To deal with this, screw type air compressors often have after - coolers and air dryers. After - coolers lower the temperature of the compressed air, causing more water to condense, which can then be drained off. Air dryers, such as refrigerated dryers or desiccant dryers, further reduce the moisture content in the air. Refrigerated dryers cool the air to a low temperature to remove most of the water vapor, while desiccant dryers use a desiccant material to adsorb the remaining moisture.

Solid particles are also a concern. These can come from the intake air, which may contain dust, dirt, and other debris. Compressors usually have air filters at the intake to prevent large particles from entering the compressor. However, over time, these filters can become clogged, reducing their effectiveness. Regular maintenance, including filter replacement, is crucial to ensure that the compressor continues to produce clean air.

The purity class of the compressed air is a way to standardize the air quality. The ISO 8573 - 1 standard defines different purity classes based on the levels of oil, water, and solid particles in the compressed air. For example, Class 1 air has extremely low levels of contaminants, suitable for applications like food and beverage production, pharmaceutical manufacturing, and electronics manufacturing. Class 2 and 3 are less pure but still meet the requirements for many general industrial applications.

The air quality output also depends on the operating conditions of the compressor. If the compressor is operating in a dirty or humid environment, it will be more challenging to maintain high - quality compressed air. For instance, if the intake air is taken from an area with a lot of dust, the air filters will have to work harder, and the risk of solid particle contamination in the compressed air will be higher. Similarly, in a high - humidity environment, the water removal systems will need to be more efficient to keep the air dry.

Another factor is the age and condition of the compressor. As a compressor gets older, its components may wear out, and the efficiency of its filtration and separation systems may decrease. This can lead to an increase in the level of contaminants in the compressed air. Regular maintenance, including checking and replacing worn parts, is essential to keep the compressor operating at its best and maintain good air quality.

So, why does air quality matter? Well, in many industrial processes, the quality of the compressed air can have a big impact on the final product. In the food and beverage industry, for example, any contamination in the compressed air can lead to spoilage or health risks. In the automotive industry, clean compressed air is needed to ensure the proper operation of paint spray guns and other pneumatic equipment. In the electronics industry, even a small amount of contamination can damage sensitive electronic components.

As a supplier of Screw Type Air Compressor, we understand the importance of providing high - quality air compressors that can produce clean and reliable compressed air. We offer a range of compressors with different features and specifications to meet the diverse needs of our customers. Whether you need a compressor for a small workshop or a large industrial plant, we can help you find the right solution.

If you're in the market for a screw type air compressor and are concerned about air quality, don't hesitate to reach out. We can provide detailed information about the air quality output of our compressors, as well as advice on the best filtration and drying systems for your specific application. Contact us today to start a conversation about your requirements and how we can help you get the best air quality from your compressor.

In conclusion, the air quality output of a screw type air compressor is influenced by factors such as the presence of contaminants, the design and quality of the compressor's filtration and separation systems, operating conditions, and the age and condition of the compressor. By understanding these factors and taking appropriate measures, such as regular maintenance and the use of high - quality filtration and drying equipment, you can ensure that your compressor produces clean and reliable compressed air for your industrial needs.

If you're interested in learning more or making a purchase, feel free to get in touch with us. We're here to assist you with all your screw type air compressor needs.

References:

- ISO 8573 - 1: Compressed air - Part 1: Contaminants and purity classes

- Various technical manuals from screw type air compressor manufacturers