Vibration is a critical parameter when it comes to the performance and longevity of a three - phase screw air compressor. As a trusted supplier of these compressors, understanding and communicating the vibration level is of utmost importance. In this blog, we will delve into what the vibration level of a three - phase screw air compressor is, why it matters, and how to manage it effectively.

Understanding Vibration in Three - Phase Screw Air Compressors

Vibration in a three - phase screw air compressor is the mechanical oscillation or movement that occurs during its operation. It is a natural by - product of the internal processes within the compressor, such as the rotation of the screw elements, the movement of the motor, and the flow of air and oil. These components are in constant motion, and any imbalance, misalignment, or mechanical defect can lead to increased vibration levels.

The vibration level is typically measured in terms of amplitude and frequency. Amplitude refers to the maximum displacement of the vibrating object from its equilibrium position. A higher amplitude indicates a more significant movement and can potentially cause more damage to the compressor and its surrounding components. Frequency, on the other hand, is the number of oscillations per unit of time, usually measured in Hertz (Hz). Different frequencies can be associated with different sources of vibration, such as the rotational speed of the screw elements or the frequency of the power supply.

Why Vibration Level Matters

The vibration level of a three - phase screw air compressor is not just a technical detail; it has significant implications for the compressor's performance, reliability, and safety.

Performance

Excessive vibration can lead to a decrease in the compressor's efficiency. When the compressor vibrates, it consumes more energy to maintain its operation. This is because the energy is being wasted on unnecessary mechanical movement rather than being used to compress the air. As a result, the compressor may require more power to achieve the same level of air output, leading to higher operating costs.

Reliability

High vibration levels can also cause premature wear and tear on the compressor's components. The constant shaking can loosen bolts and connections, leading to leaks and malfunctions. It can also cause damage to the bearings, seals, and other critical parts, reducing their lifespan and increasing the likelihood of breakdowns. Over time, this can result in costly repairs and downtime, which can disrupt your business operations.

Safety

In extreme cases, excessive vibration can pose a safety hazard. If the vibration is severe enough, it can cause the compressor to become unstable, increasing the risk of it tipping over or coming loose from its mounting. This can not only damage the compressor but also pose a danger to nearby personnel. Additionally, the vibration can generate noise, which can be a nuisance and potentially harmful to the hearing of those working in the vicinity.

Factors Affecting Vibration Level

Several factors can influence the vibration level of a three - phase screw air compressor. Understanding these factors can help you identify potential issues and take appropriate measures to manage the vibration.

Installation

Proper installation is crucial for minimizing vibration. If the compressor is not installed on a level and stable surface, it can cause uneven stress on the components, leading to increased vibration. Additionally, the alignment of the motor and the screw elements must be precise. Misalignment can cause the compressor to vibrate excessively, even if the components are in good condition.

Maintenance

Regular maintenance is essential for keeping the vibration level in check. Over time, the compressor's components can wear out, become dirty, or develop mechanical problems. For example, worn bearings can cause the screw elements to vibrate more than normal. By performing regular maintenance tasks, such as lubrication, filter replacement, and alignment checks, you can ensure that the compressor is operating smoothly and minimize the risk of excessive vibration.

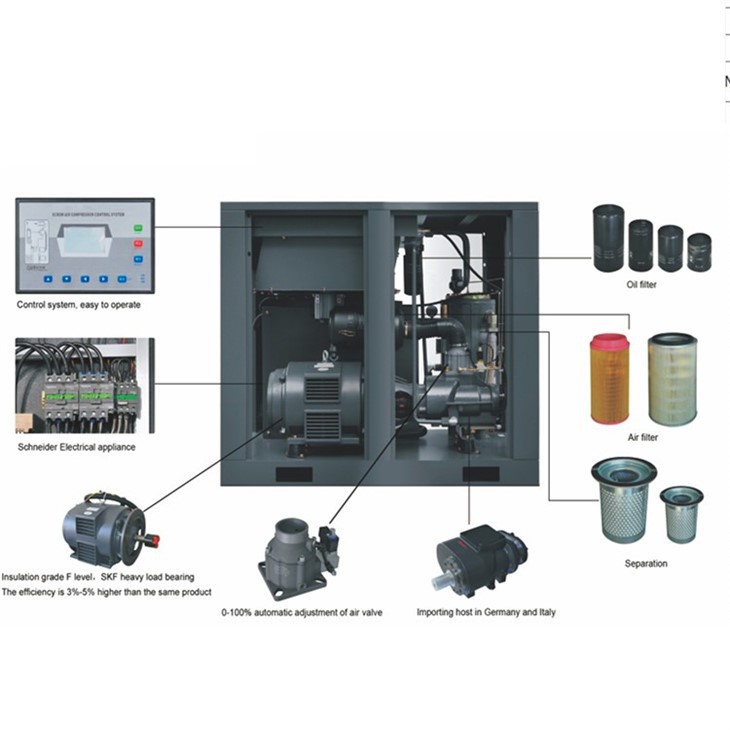

Design and Quality

The design and quality of the compressor also play a significant role in determining its vibration level. High - quality compressors are typically designed with features that reduce vibration, such as balanced rotors and vibration - dampening materials. Additionally, the manufacturing process can affect the precision of the components, which can impact the vibration level. As a [Your Company Position] at a leading supplier of three - phase screw air compressors, we ensure that our products are designed and manufactured to the highest standards to minimize vibration.

Measuring and Monitoring Vibration Level

To effectively manage the vibration level of a three - phase screw air compressor, it is important to measure and monitor it regularly. There are several tools and techniques available for measuring vibration, including accelerometers, vibration meters, and laser alignment tools.

Accelerometers are devices that measure the acceleration of the vibrating object. They can be attached to the compressor at various points to measure the vibration amplitude and frequency. Vibration meters, on the other hand, are handheld devices that can provide a quick and easy way to measure the overall vibration level. Laser alignment tools are used to ensure that the motor and the screw elements are properly aligned, which can help reduce vibration.

By monitoring the vibration level over time, you can detect any changes or trends that may indicate a problem. For example, if the vibration level suddenly increases, it could be a sign of a mechanical issue, such as a worn bearing or a loose bolt. By taking prompt action, you can prevent the problem from worsening and avoid costly repairs.

Managing Vibration Level

If you find that the vibration level of your three - phase screw air compressor is higher than normal, there are several steps you can take to manage it.

Adjust the Installation

If the compressor is not installed correctly, adjusting the installation can often reduce the vibration level. Make sure that the compressor is installed on a level and stable surface, and that the mounting bolts are tightened properly. You may also need to check the alignment of the motor and the screw elements and make any necessary adjustments.

Perform Maintenance

Regular maintenance is key to managing vibration. As mentioned earlier, worn components can cause increased vibration. By performing routine maintenance tasks, such as lubrication, filter replacement, and bearing inspection, you can keep the compressor in good condition and minimize the risk of excessive vibration.

Upgrade the Compressor

In some cases, upgrading the compressor may be necessary to reduce the vibration level. If your compressor is old or outdated, it may not have the latest features and technologies that are designed to reduce vibration. Upgrading to a newer, high - quality compressor can not only reduce the vibration but also improve the compressor's performance and reliability.

As a supplier of three - phase screw air compressors, we offer a wide range of products that are designed to meet the needs of various industries. Our Industrial Use Screw Air Compressor is suitable for heavy - duty applications, while our Rotary Screw Air Compressor is known for its energy efficiency and reliability. We also have a variety of Screw Type Air Compressor models to choose from, each with its own unique features and benefits.

Conclusion

The vibration level of a three - phase screw air compressor is a critical parameter that can have a significant impact on the compressor's performance, reliability, and safety. By understanding what the vibration level is, why it matters, and how to manage it, you can ensure that your compressor operates smoothly and efficiently.

If you are in the market for a three - phase screw air compressor or need assistance with managing the vibration level of your existing compressor, we are here to help. Our team of experts can provide you with the latest information and advice on choosing the right compressor for your needs and ensuring its proper installation and maintenance. Contact us today to start a conversation about your air compressor requirements and let us help you find the best solution for your business.

References

- Compressor Handbook, Third Edition, by Klaus Brun and Eckard Specht

- Vibration Analysis for Rotating Machinery, by Robert B. Randall and John D. Antoniou

- Industrial Air Compressor Systems: Operation, Maintenance, and Troubleshooting, by Timothy H. Faires