In the realm of industrial machinery, the rotary screw air compressor stands as a cornerstone of efficient air compression technology. As a leading supplier of Rotary Screw Air Compressors, I've witnessed firsthand the pivotal role that the motor plays in these sophisticated machines. In this blog post, I'll delve into the intricacies of the motor's function within a rotary screw air compressor, exploring its significance, operation, and impact on overall performance.

The Heart of the Compressor: Understanding the Motor's Role

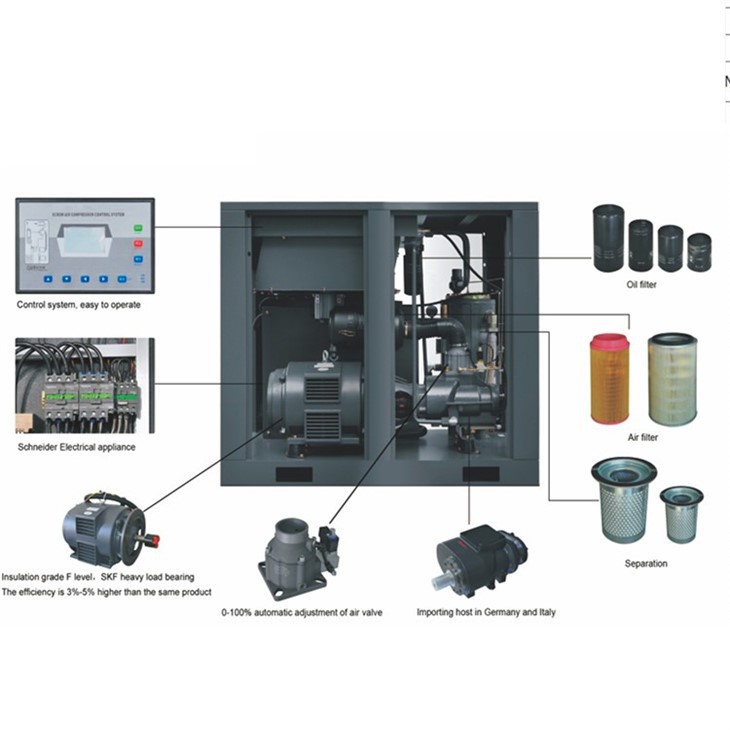

At its core, the motor in a rotary screw air compressor serves as the primary power source, driving the rotation of the compressor's twin screws. These screws, also known as rotors, are the heart of the compression process, drawing in ambient air and compressing it to a higher pressure. The motor provides the necessary torque and rotational force to turn the rotors at a consistent speed, ensuring efficient and reliable air compression.

One of the key functions of the motor is to maintain a stable and consistent speed of rotation. This is crucial for the proper operation of the compressor, as any fluctuations in speed can lead to variations in air pressure and flow rate. To achieve this, most rotary screw air compressors are equipped with a motor that is specifically designed to operate at a fixed speed, typically between 1,500 and 3,600 revolutions per minute (RPM). This ensures that the compressor can deliver a steady supply of compressed air at a constant pressure, regardless of the demand.

In addition to providing the necessary power for rotation, the motor also plays a vital role in controlling the compressor's start and stop functions. When the compressor is turned on, the motor receives an electrical signal that activates it, causing the rotors to begin spinning. Once the desired air pressure is reached, the motor is automatically shut off, preventing the compressor from over-pressurizing. This automatic control system helps to conserve energy and extend the lifespan of the compressor by reducing wear and tear on the components.

Types of Motors Used in Rotary Screw Air Compressors

There are several types of motors that can be used in rotary screw air compressors, each with its own unique characteristics and advantages. The most common types of motors used in these applications include:

- Single-Phase Motors: Single-phase motors are typically used in smaller rotary screw air compressors, with power ratings ranging from 1 to 5 horsepower (HP). These motors are designed to operate on a single-phase electrical supply, which is commonly available in residential and small commercial settings. Single-phase motors are relatively inexpensive and easy to install, making them a popular choice for applications where cost is a primary consideration.

- Three-Phase Motors: Three-phase motors are the most commonly used type of motor in larger rotary screw air compressors, with power ratings ranging from 5 to 500 HP or more. These motors are designed to operate on a three-phase electrical supply, which is typically available in industrial and commercial settings. Three-phase motors offer several advantages over single-phase motors, including higher efficiency, greater power output, and smoother operation. They are also more reliable and require less maintenance, making them a preferred choice for applications where continuous operation is required.

- Variable Frequency Drive (VFD) Motors: VFD motors are a type of three-phase motor that is equipped with a variable frequency drive, which allows the motor to operate at a variable speed. This provides several benefits, including energy savings, improved efficiency, and reduced wear and tear on the compressor components. VFD motors are typically used in applications where the demand for compressed air varies frequently, such as in manufacturing plants and automotive workshops.

Factors Affecting Motor Performance

The performance of the motor in a rotary screw air compressor can be affected by several factors, including:

- Power Rating: The power rating of the motor is one of the most important factors that determines its performance. A motor with a higher power rating will be able to provide more torque and rotational force, allowing the compressor to operate at a higher pressure and flow rate. However, it's important to choose a motor with a power rating that is appropriate for the specific application, as an oversized motor can be inefficient and waste energy.

- Efficiency: The efficiency of the motor is another important factor that affects its performance. A more efficient motor will convert a higher percentage of the electrical energy it consumes into mechanical energy, resulting in lower energy costs and reduced environmental impact. When choosing a motor for a rotary screw air compressor, it's important to look for a motor with a high efficiency rating, such as an Energy Star-certified motor.

- Cooling System: The cooling system of the motor is also crucial for its performance. A motor that operates at a high temperature can experience reduced efficiency and reliability, and may even fail prematurely. To prevent this, most motors are equipped with a cooling system, such as a fan or a water jacket, to dissipate heat and keep the motor operating at a safe temperature.

- Maintenance: Regular maintenance of the motor is essential for ensuring its optimal performance and longevity. This includes tasks such as lubrication, cleaning, and inspection of the motor components. By following the manufacturer's recommended maintenance schedule, you can help to prevent breakdowns and extend the lifespan of the motor.

Importance of Choosing the Right Motor

Choosing the right motor for a rotary screw air compressor is crucial for ensuring its optimal performance and reliability. A motor that is too small for the application may not be able to provide enough power to drive the compressor, resulting in reduced air pressure and flow rate. On the other hand, a motor that is too large for the application can be inefficient and waste energy, leading to higher operating costs.

When choosing a motor for a rotary screw air compressor, it's important to consider several factors, including the power rating, efficiency, cooling system, and maintenance requirements. You should also consult with a qualified compressor technician or engineer to ensure that you choose a motor that is compatible with the specific compressor model and application.

Conclusion

In conclusion, the motor plays a critical role in the operation of a rotary screw air compressor. It provides the necessary power for rotation, controls the start and stop functions, and helps to maintain a stable and consistent speed of operation. By choosing the right motor for the application and ensuring its proper maintenance, you can help to ensure the optimal performance and reliability of your compressor.

If you're in the market for a Rotary Screw Air Compressor, Industrial Use Screw Air Compressor, or Three Phase Screw Air Compressor, I encourage you to contact us to discuss your specific needs. Our team of experts can help you choose the right compressor and motor for your application, and provide you with the support and service you need to keep your equipment running smoothly.

References

- Compressed Air and Gas Institute (CAGI). (2023). Rotary Screw Compressors: Principles and Applications.

- ASME. (2023). Performance Testing of Rotary Screw Compressors.

- IEEE. (2023). Standard for Electric Motors and Generators.