Hey there! I'm a supplier of Rotary Screw Air Compressors, and today I wanna talk about something super important: the effect of water in the air on these compressors.

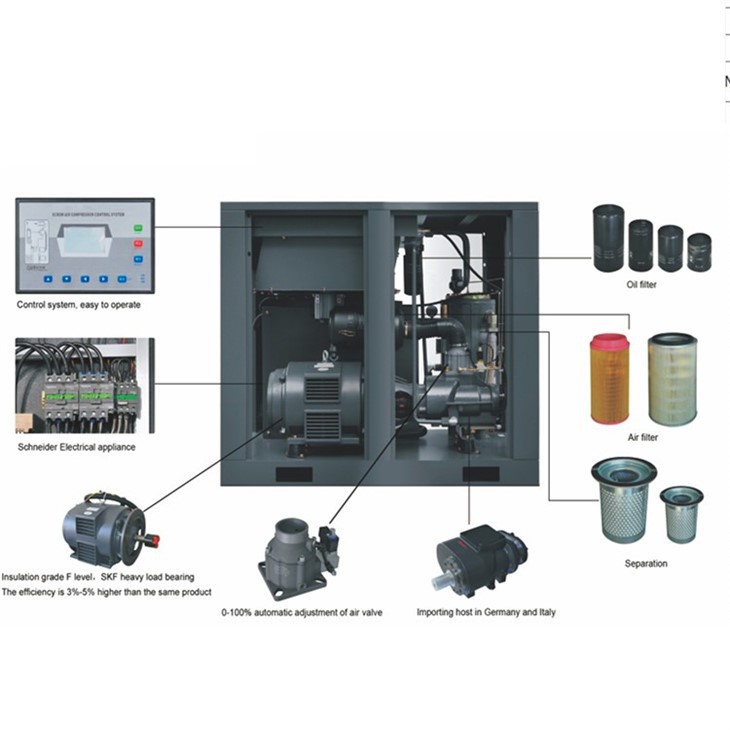

First off, let's understand how a Rotary Screw Air Compressor works. It's a pretty cool piece of machinery. Air gets sucked in through an intake valve. Then, it goes between two rotating screws, which compress the air to a higher pressure. This compressed air is then used for all sorts of industrial and commercial applications. You can learn more about it here: Rotary Screw Air Compressor.

Now, water in the air is a common thing. Air usually has some amount of moisture in it, and this can have a big impact on the performance and lifespan of a Rotary Screw Air Compressor.

Corrosion

One of the most obvious effects of water in the air is corrosion. When water vapor in the air gets compressed, it can turn into liquid water. This liquid water can accumulate inside the compressor. The metal parts of the compressor, like the screws, valves, and pipes, are at risk of rusting. Rust weakens the metal, which can lead to leaks, reduced efficiency, and even complete failure of the compressor. For example, if the screws start to corrode, they won't be able to compress the air as effectively, and the compressor will have to work harder to achieve the same pressure. This not only wastes energy but also shortens the lifespan of the compressor. To avoid this, it's important to have proper drainage systems in place to remove the condensed water. And if you're looking for a reliable Rotary Screw Air Compressor that's built to handle these issues, we've got you covered.

Lubrication Problems

Most Rotary Screw Air Compressors use oil for lubrication. Water can mix with the oil, forming an emulsion. This emulsion is not as effective as pure oil for lubricating the moving parts of the compressor. When the lubrication is poor, there's more friction between the parts. This friction generates heat, which can cause the parts to wear out faster. Also, the heat can break down the oil further, reducing its lubricating properties even more. In extreme cases, the lack of proper lubrication can lead to seizing of the compressor, which is a major problem. To prevent this, regular oil changes and the use of oil separators are necessary. The oil separator helps to remove the water from the oil, ensuring that the compressor gets the proper lubrication it needs.

Contamination of Compressed Air

The water in the compressed air can also contaminate the end - use applications. Many industries, such as food and beverage, pharmaceuticals, and electronics, require clean and dry compressed air. If there's water in the compressed air, it can carry dirt, bacteria, and other contaminants. In the food and beverage industry, for example, this can lead to product spoilage. In the electronics industry, water can damage sensitive electronic components. That's why it's crucial to have air dryers installed after the compressor to remove the moisture from the compressed air. Our Industrial Use Screw Air Compressor can be equipped with high - quality air dryers to meet the strict requirements of these industries.

Reduced Efficiency

Water in the air can also reduce the overall efficiency of the compressor. When the compressor has to compress air that contains water vapor, it's essentially compressing both air and water. The water doesn't contribute to the useful work of the compressor. In fact, it takes up space and energy that could be used to compress more air. This means that the compressor has to work harder to achieve the same amount of compressed air output. As a result, the energy consumption of the compressor increases, and the operating costs go up. By removing the water from the intake air or the compressed air, the compressor can operate more efficiently, saving you money in the long run.

Impact on Controls and Sensors

Modern Rotary Screw Air Compressors are equipped with various controls and sensors to monitor and regulate their operation. Water can damage these controls and sensors. For example, if water gets into an electronic sensor, it can cause inaccurate readings. This can lead to improper operation of the compressor, such as over - or under - pressurization. In some cases, it can even trigger false alarms, causing unnecessary shutdowns. To protect these important components, proper sealing and ventilation are required. And we make sure that our compressors are designed to minimize the risk of water damage to the controls and sensors.

Solutions to Mitigate the Effects of Water

There are several ways to deal with the water in the air and its effects on the Rotary Screw Air Compressor. First, using air filters at the intake can help to remove some of the moisture and contaminants from the incoming air. Second, installing air dryers, such as refrigerated dryers or desiccant dryers, can effectively remove the water from the compressed air. Third, regular maintenance, including checking and cleaning the drainage systems, changing the oil, and inspecting the components for corrosion, is essential. By taking these steps, you can ensure that your compressor operates smoothly and efficiently for a long time.

Conclusion

In conclusion, water in the air can have a significant impact on the performance, efficiency, and lifespan of a Rotary Screw Air Compressor. From corrosion and lubrication problems to contamination of compressed air and reduced efficiency, the effects are far - reaching. But with the right equipment and maintenance, these problems can be mitigated. As a supplier of Rotary Screw Air Compressors, we understand these issues well and offer high - quality compressors and solutions to meet your needs. Whether you're in a small workshop or a large industrial plant, we've got the right compressor for you.

If you're interested in learning more about our Rotary Screw Air Compressors or have any questions about dealing with water in the air, don't hesitate to contact us. We're always ready to have a chat and help you find the best solution for your business. Let's work together to ensure that your operations run smoothly and efficiently.

References

- Compressed Air and Gas Institute (CAGI). "Compressed Air Best Practices."

- Pneumatic Handbook, various editions.

- Manufacturer's manuals for Rotary Screw Air Compressors.